High Pressure – a Green Future

There are so many industries that use high pressure. This could be through pumps, compressors or vacuum. And they all have one thing in common. They, like us, are part of the green future. The energy transition. The drive towards net zero. Without doubt, they/we have to be!

We can say truthfully that we want to be green, and perhaps it could be our mission. However, it’s what the customers want that really matters. And industry is increasingly demanding pumping equipment for renewable energy applications and equipment powered by renewable energy. If we are to thrive as a company, we must continue to adapt to our customers’ needs. In essence, we must build flow solutions that meet the ever-changing demands of industry.

As a result, much talk at Calder over the last few years, and even more recently, has been about two things. Firstly, how can our machines utilise green energy sources for their own power. And secondly, what high pressure pump, compressor and vacuum packages will support the emerging zero carbon industries. In both cases, it is our huge design and engineering experience, coupled with a smattering of entrepreneurship, that will ensure our company is part of the solution to our environmental issues.

High Pressure - Product Design for Green Energy

For some time, we have been developing our product range to meet the climate targets this world needs to achieve. Much thought has been given to our aim of making our pump units operationally zero emissions. Similarly, where do our products fit within the developing post-carbon industries? This is an evolution, not revolution, of product design that takes with it the tenets of quality and reliability on which our company’s success is based.

MultiJet – Mobile, Road-going, Waterjet Pumps

Operators need mobile waterjetting equipment that produces pressures up to 4,000 bar. Industry uses these units for concrete hydrodemolition, surface preparation, tube and tank cleaning and much more. Frequently, the work site is remote from a power supply and diesel engines are the only current, viable option. In the short term, all of our road-going units benefit from the incorporation of a Stage 5 engine. The Stage 5 power unit uses the very latest in ultra-low emissions technology.

We are now working on the next generation of these mobile waterjetting pumps. The two main renewables technologies we are looking at present very different challenges. The first requires few design modifications, but the infrastructure isn’t quite there yet. The other requires fundamental changes to our design to accommodate the technology. And whichever of the options we choose, we will need to future proof the design to align with the rapidly advancing technology.

Water Recycling and Filtration

The advantages of using high pressure water for cleaning and surface preparation are many. There are no chemicals or abrasives required – just water. Options are available to alter the pressure to suit different materials, and the process returns metals to their original surface profile. And let us not forget, high pressure water is fast and efficient.

But there is more! The waste water can be filtered and recycled. This is ideal where water is scarce or the supply suffers from frequent interruptions. In fact, even where there are no water supply issues, recycling water has to be the best option for our environment. The used water is collected and treated for re-use or for safe discharge back to its source.

The photo shows a waste water filtration system supporting high pressure pumps on the impressive Kariba Dam Rehabilitation Project.

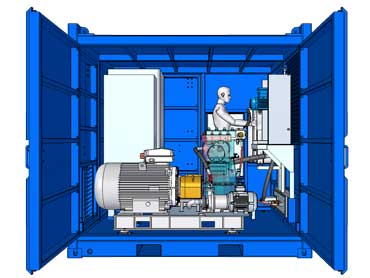

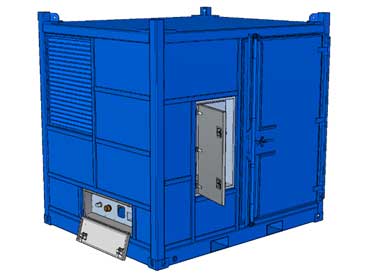

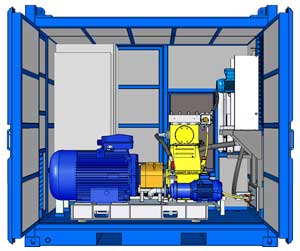

Hydrogen, CCUS and Geothermal Energy

It was pleasing to see so much interest in our pump systems for hydrogen, CCUS and geothermal energy at the recent ONS 2024 exhibition in the stunning city of Stavanger, Norway. It is clear that the energy transition will be an important part of our company’s future and a natural progression for our high pressure, hazardous area pump systems..

Get in Touch

Whatever your application, we are here to help. Please call us on +44 1905 751790 or email sales@calder.co.uk to discuss how we can help you achieve your green future energy targets.